Better tooling means better stamping

Nearly half of a century of experience in the crafting of precision tool and die products has given Fayette Tool a definite advantage in producing quality stampings. As a compliment to stamping, we also offer the addition of a braze flux coating.

Total Capability. Total Quality.

Stamping

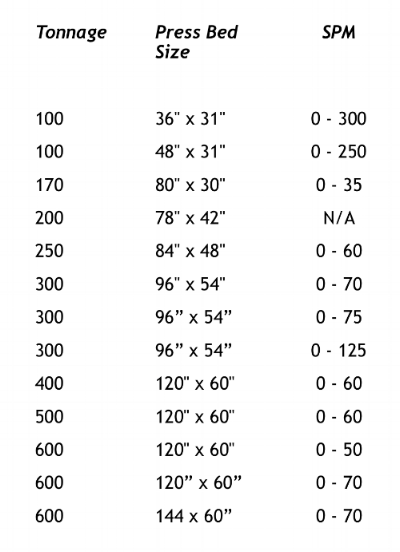

Our progressive die stamping presses range from 100 ton to 600 ton. Feed lines can handle up to 54” wide coils. Material gauges range from 0.015” (0.40mm) to 0.1181” (3.00mm). We also have hand transfer stamping presses.

Capabilities for Clad Aluminum and Aluminum

Secondary Processes

Improving our Customers’ Manufacturing Processes

In addition to an aqueous wash option, Fayette Tool also has the capability to deburr parts to assist customers with their assembly processes. We also have two complete thermal degreasing and spray flux application systems which use our particular method of applying the coating to our customers’ satisfaction. A coating can be applied to one or both sides of a stamping depending on application requirements. This supplementary value-added step allows program cost savings by eliminating the additional cost of transporting product to a third-party coating operation.