Fayette Tool has the expertise, technology, and people to provide turn-key production stamping services. Our experience in precision aluminum stamping and spray flux application makes us uniquely capable of supporting the needs of climate control applications.

MANUFACTURING

Fayette Tool specializes in aluminum stamping components for climate control applications in the automotive heat exchange industry. Manufactured products include radiator, condenser, heater core, evaporator, charge air cooler, water cooled charge air cooler, and battery cooling stampings. Aqueous cleaning, thermal degreasing, deburring, and spray flux applications are also offered to improve the quality of customer manufacturing processes.

Tooling

First and foremost it is the tooling that governs the quality and repeatability of the stampings. With an original foundation of designing and tool making, we have the gained experience and full understanding of tooling design and how to best maintain the tooling. We have onsite immediate, preventative, and predictive maintenance capabilities, with the support from our own machine shop.

Quality

Fayette Tool has certifications for both IATF 16949: 2016 and ISO 9001: 2015. Our internal laboratory is capable to perform the required inspection, testing, and calibration in house. All testing and calibration is performed with equipment traceable to NIST. Our external laboratory is accredited to ISO 17025.

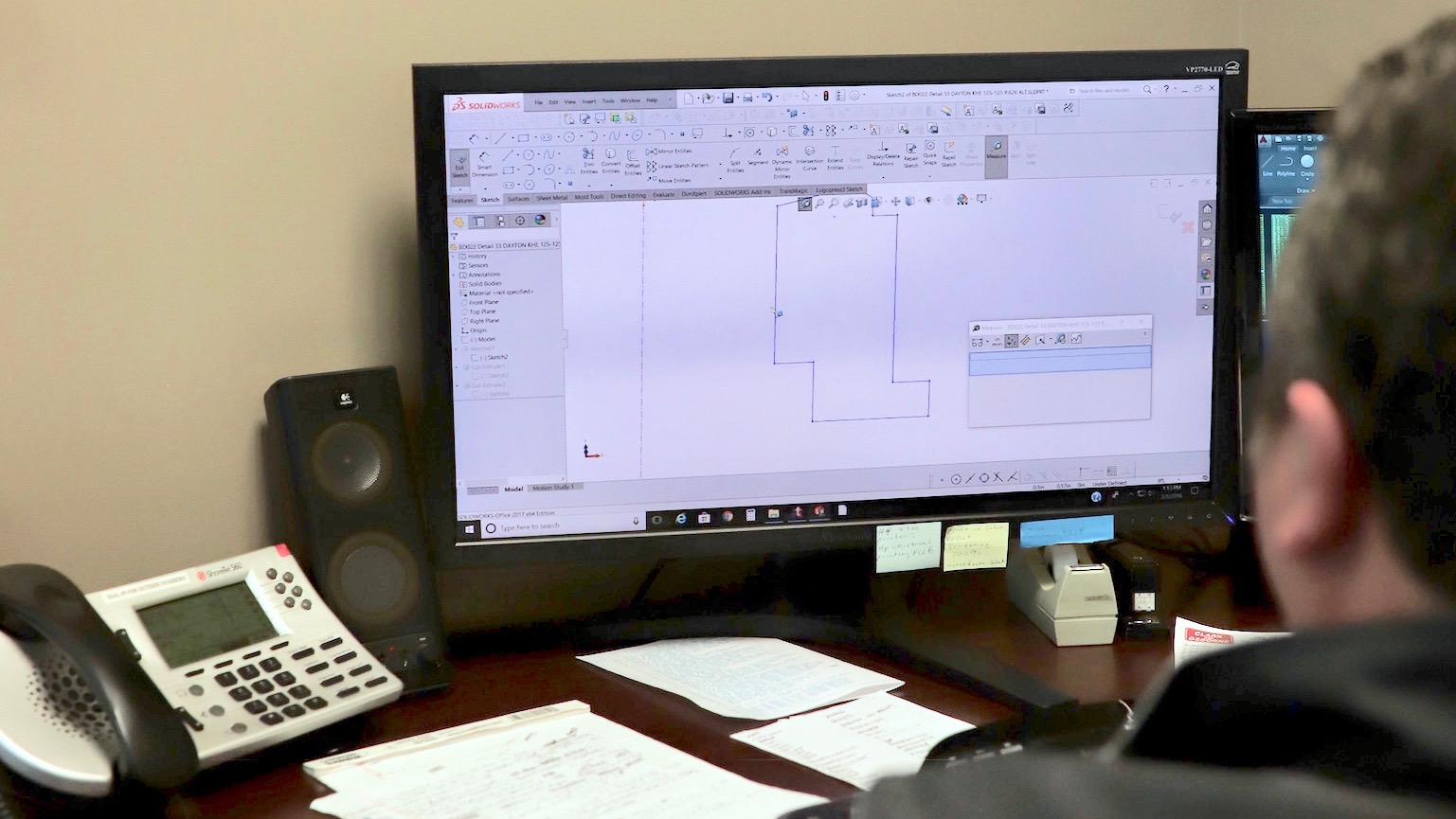

Project Management

On average, Fayette Tool Project Engineers have 24 years of automotive experience. From prototype through production, they provide outstanding support and professional customer service for product development, tool design, and project management. Technical and engineering services are supported by the latest CAD software including AutoCad and SolidWorks.